problem

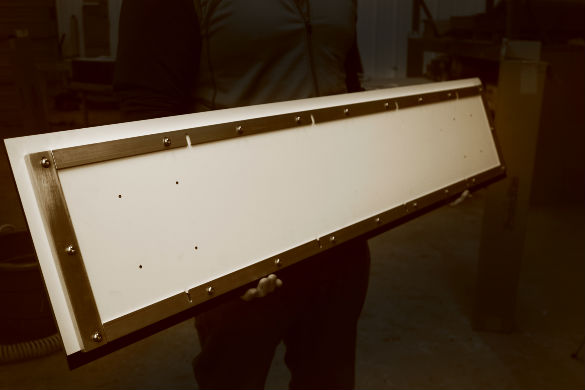

Client needed a low cost modular system that would allow individual LCD panel replacement, simple installation and a robust to handle during heavy vibrations from train movement and extreme temperatures.

process

Worked with client to identify specific design criteria, costing budget and timing. Worked with and mentored engineer to develop several concepts and 3D CAD models. Developed supply chain for client and tailored design specifics for turn key solution.

solution

Leveraged weight to strength ratio of composite laminate material as core structure. Designed simple stacked concept with alignment modules that created a high tolerance assembly with easy maintenance and repair. Final design reduced cost by 80%.